Dorchester 2 Freedom Gray Ornamental Copper Downspout Bands Straps

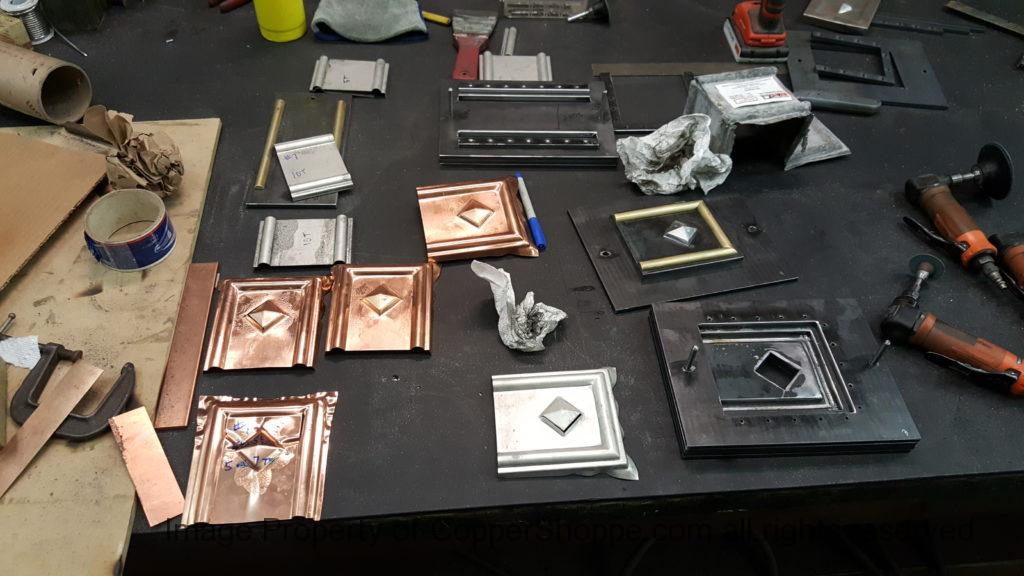

This will take awhile for this project as we are starting at Ground Zero. First was design of the Bands and then do the necessary CAD work to get the raw Die Set blanks laser cut.

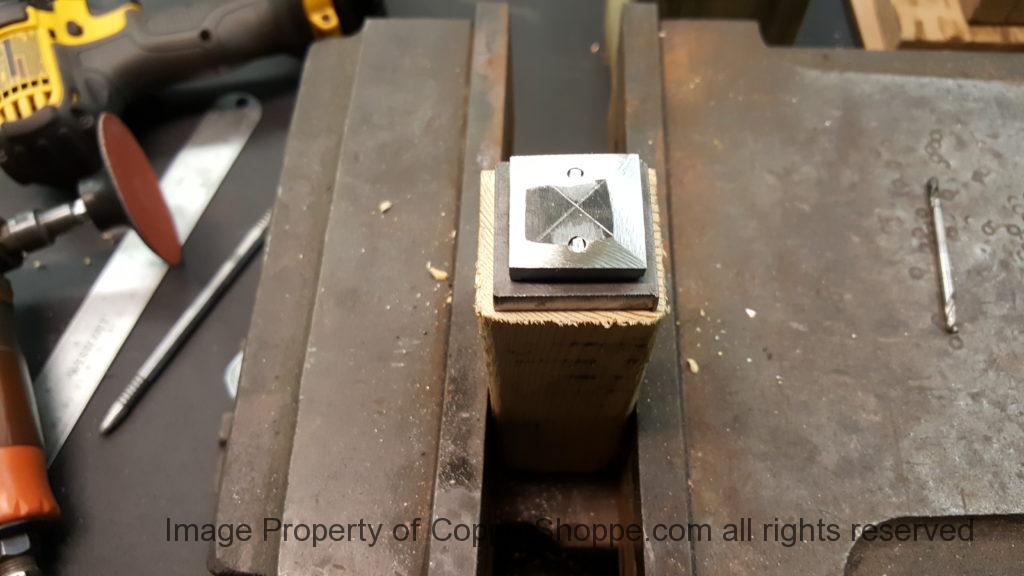

Got a lot done actually. The Button looks good for roughing in.

Day 2

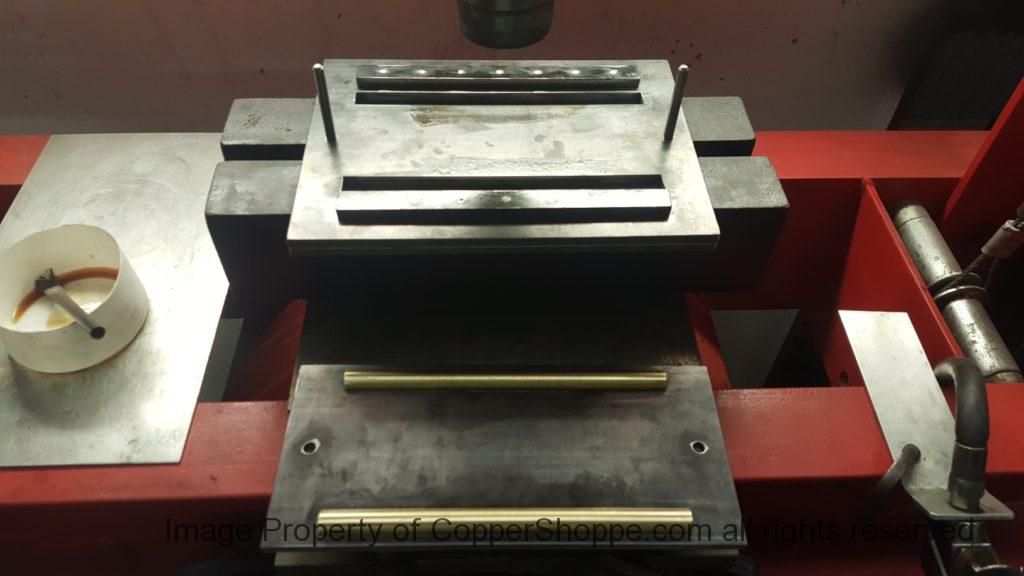

Working on die sets for the faces and sides (actually its the same die set as they are the same shape just different lengths and miters for the parts they will make).

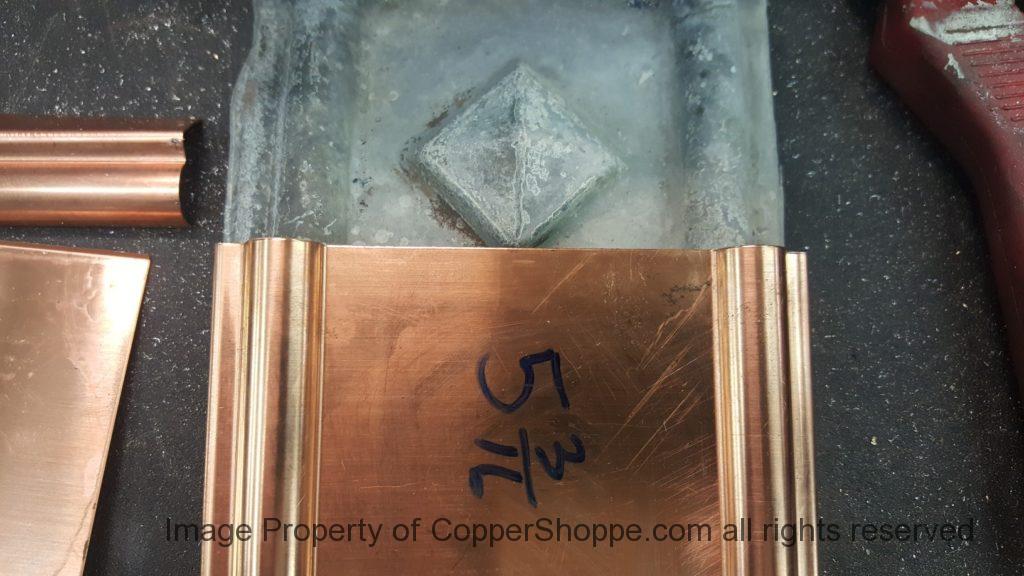

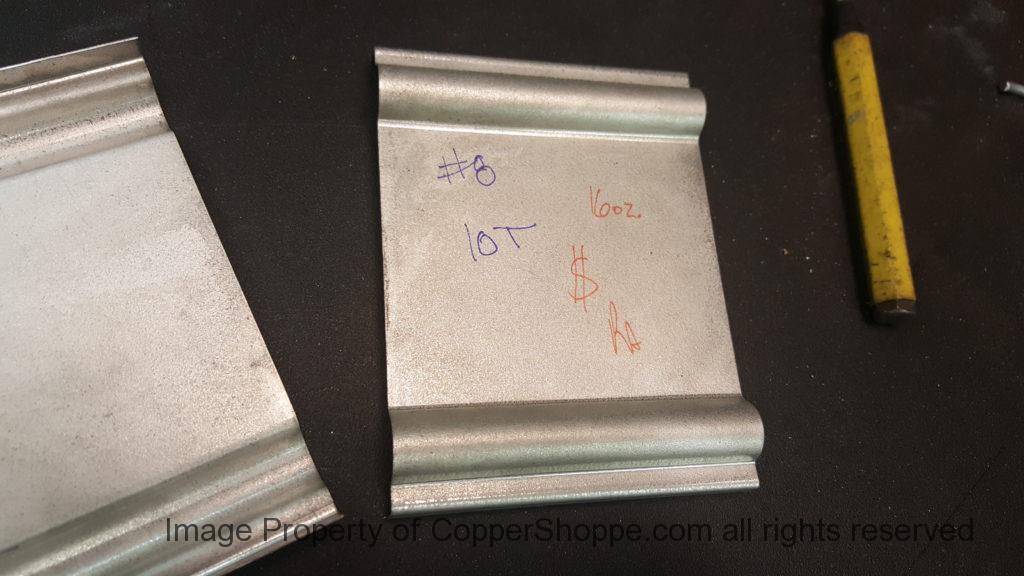

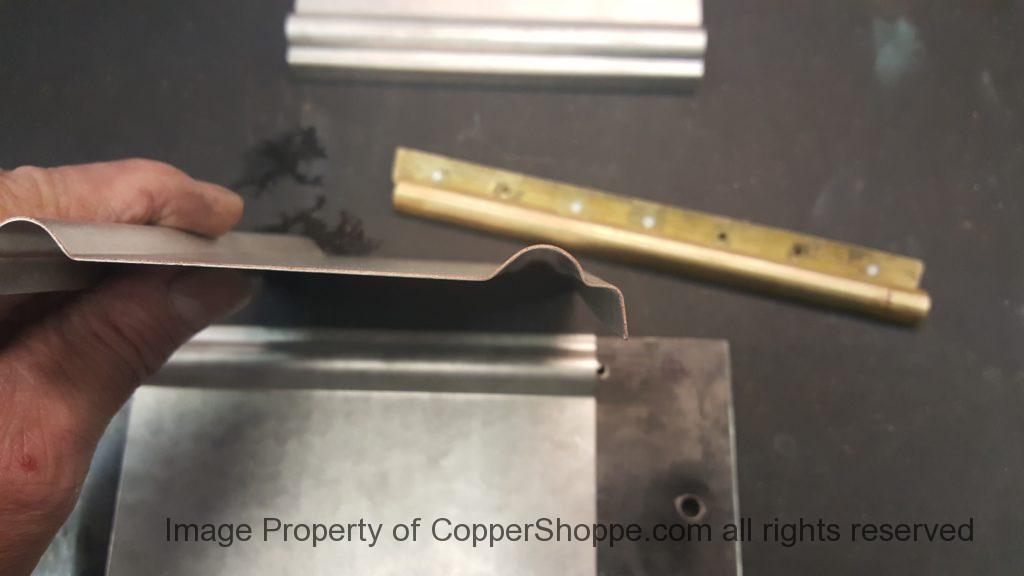

Ok. Proved out the blank needs to be 5-3/16″ wide and had to take off more in areas of the die set parts as they actually pinched so tight that the copper sheared. Went up to the 16 oz. Freedom Gray and got “Die Lock” meaning the extra thickness wouldn’t let the punch and die fully engage but locked up before bottoming out. See the last picture above. Part not fully formed on one side. We are at 5 ton hit level right now.

Day 3

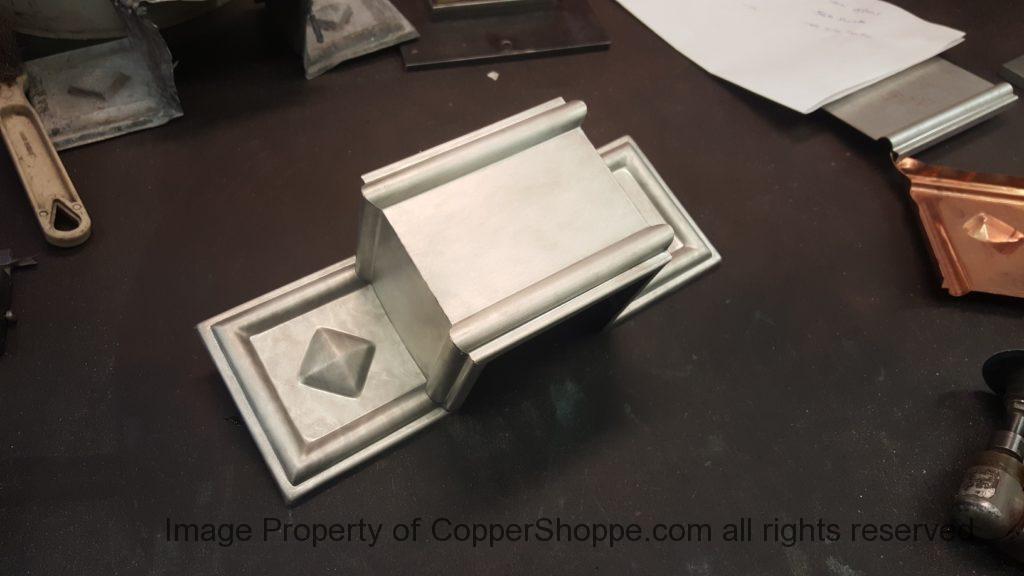

So once we took out enough material to let the punch and die fully engage we got the same issue as the first hit in copper. More grinding. Another Hit in the press. More Grinding etc. Got things on the money on the 8th trial at 10 Tons (more than we probably have to use in production but if you are good at over tonnage you will always have good parts at 7 Tons – thinking this will be a 7 ton hit in production). Customer is sending us samples of 20 oz. Freedom Gray. When we get that it will be the same process. Probably get a tear out and have to do more grinding. But at least that will now be minimal and we know what to look for regarding problem areas.

Now to start on the “Ears” Die Sets…. Very – Very tricky. We are going to attempt to punch in the Buttons in the Ears. Buttons are Big and Deep – will require a lot of material draw. It is Saturday at 2:42 as I write this. See how far I get in a few hours….

Day 4

Sunday

Well in a nut shell problematic. We proved out the Ear prototype pretty well and then jumped to the buttons…. Loads of fun. It took us 8 hits to get the ear right. Pictures are not really shown of that as I had no time to document. My main concern was the buttons…

We knew this was going to be a tough one. Material Freedom Gray. Material 20 oz. and a design that is not forgiving as material is trapped during the forming process that is not forgiving to Pull factor required to make the profile as the pulls add up and ultimately end up as a tear out. We did the same thing as far as order goes…prove out in 16 oz. copper – move up to 20 oz. copper – then go to 16 oz. Freedom Gray. We are close but not there yet. Again the customer is sending us some 20 oz. Freedom Gray for the first band sample as we currently have no 20 oz. Freedom Gray in stock. Tomorrow is Monday so going to take a break off this and go back to the Freedom Gray Leader Box project. Prototype is costly. We are probably $1,200.00 plus invested in this project at this point and have a way to go to get a good “Sample”. Projection would be $1,500.00 before it is all done and over and ready for production. That is if we can get a good looking button stamped into the ears. If the designer balks on that add another $150.00 (we already laser cut the blanks as a back up so that cost is in the mix already) so just prove out for that if necessary. Appliques are a time consuming effort. This job is 130 plus bands so that would be 260 plus buttons… would really like to get pressed in approved! Separate Buttons would cost $12.00 each plus $3.50 for soldering the 12 ga. wire and then the button installation time. $4,030.00 might seem like a lot of money and a nice pop for sales but quite frankly I would rather pass on that option and get through the pressed in stage (which we do at no charge) approved by the designer and have this aspect of the project behind us.

Day 5

Proved out everything and next is setting up to miter and assemble.

Day 6

Finally have the first one done!

Will be shipping this First One later today so we can ultimately get the designers approval. Whew!

8/13/2017

It’s Sunday and making a Second Band for the Builder this time now…..

We had some minor issues that we will be correcting on the second band. The radius for the Front and Sides (same die sets) were just a little bit off where we would like them to be. Made the corrections.

If you look really close in the end view of the parts you can see the tear drop shape as opposed to a true radius….Fixed! Should be ready to roll now….

Project Approved!

Link to Recent Projects for the first 50: https://www.coppershoppe.com/dorchester-2-freedom-gray-copper-ornamental-downspout-bands-straps-2/

This project will take over a year to complete. This Building at Harvard that these are being installed on will be done in segments. The Roofing and Guttering related costs are over 8 million dollars and has a lot of coordination issues to work out to get things done properly. So you will see periodic postings of the progress of this project as things get developed and as they are accomplished in our Recent Projects Blog. We will also be doing Custom Leader Boxes as well.

We have done numerous projects for Harvard (via various contractors) to date and look forward to doing more from them!

Leave A Comment